Producing responsibly

The organisation is the cornerstone of our Corporate system, which is built on a clear and efficient architecture consisting of a group of people, processes and materials bound by daily actions and skilfully guided to identify objectives, practices, key issues and inspirations. Our product development is the result of our realisation that the impact of the production process along the entire value chain is increasingly important in view of the sustainability path we have chosen to pursue.

The organisation is the cornerstone of our Corporate system, which is built on a clear and efficient architecture consisting of a group of people, processes and materials bound by daily actions and skilfully guided to identify objectives, practices, key issues and inspirations. Our product development is the result of our realisation that the impact of the production process along the entire value chain is increasingly important in view of the sustainability path we have chosen to pursue.

We consciously reuse all types of materials.

When it comes to sustainability, discussion is often limited to the production processes alone. We, on the other hand, focus on the entire production chain, from the materials used to the packaging, all the way through to a product’s end-of-life. Thanks to the specific life cycle studies we conduct on our products, we successfully and constantly pursue our circular economy model.

Waste becomes a precious resource.

We are committed to minimising the waste of resources to reduce negative environmental impacts by reusing production waste in the manufacturing process to make new products.

Thanks to our research and development department, we have further refined the research of bio-based, compostable or recycled materials for the realization of our products.

In 2023 we also perfected the processes of reuse of our production waste by reimposing more than 200 tons of production waste in the production cycle, which until some time ago would have been landfilled as industrial waste.

The LCA project

The LCA methodology - Life Cycle Assessment - is the ideal approach to analyze and communicate the environmental performance of our product lines, as it considers all phases of the life cycle allowing us to evaluate the different "impact categories".

This analysis, the methodological basis for adherence to national and international standards, which allows us to communicate data according to scientific methods, is based on the following reference standards:

- UNI EN ISO 14040:2021 Environmental Management, Life Cycle Assessment, Principles and Frameworks

- UNI EN ISO 14044:2021 Environmental Management, Life Cycle Assessment, Requirements and Guidelines

We started by analyzing a product line that for us is a core-business or the channels for air conditioning and accessories Optima analyzing the purchase process, the production, the distribution channel, use and maintenance until the product is disposed of.

The report that emerged allows us to share results and continuous improvement actions.

In 2024 we will extend this methodology to the most sold product families in 2023.

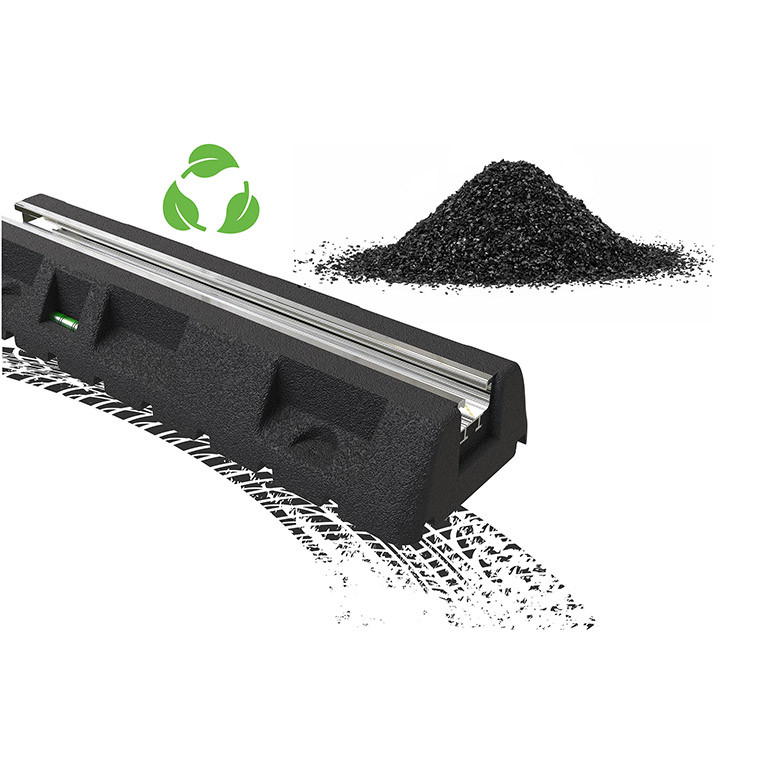

Our Extreme vibration dampers are made with rubber derived from recycled used tyres.

Since they were first invented, tyres have revolutionised a concept of mobility and the rubber with which they are produced is truly irreplaceable but, like all highly wearable materials, they too reach their end of life.

It is common belief that the rubber they are made of is not easy to dispose of but with the right research and process tools, it becomes a highly recyclable material which, when shredded, is reduced to granules.

Our Extreme vibration damping bases are created from these recovered vulcanised rubber granules: the positive results include not only the reduced environmental impact linked to the disposal of the tyre but also reduced energy consumption, since the production of recycled rubber requires less energy compared to virgin rubber.

Energy audit of our production plant

Energy audit is a functional analysis tool that allows us to reduce any inefficiencies in our energy consumption processes. It also allows us to evaluate investments in new high efficiency plants and renewable sources for a proper management of our annual consumption.

It is based on the technical standard of reference: UNI CEI EN 16247.

In 2023, thanks to a team effort, we conducted the first reference energy audit, obtaining a real energy diagnosis report containing some recommendations for improving efficiency with a proposal for a plan of measures and verifications.

We will repeat this analysis every five years to monitor and analyze the efficiency of our plants.

Even packaging can become sustainable.

We recycle paper and cardboard as fillers in the packaging we send to our clients, thus eliminating the plastic used to ship our products. Through a study and research into our circularity, we are introducing several different improvement actions aimed at increasing the use of bio-based, biodegradable, recyclable or recycled materials, pursuing increasingly sustainable choices.

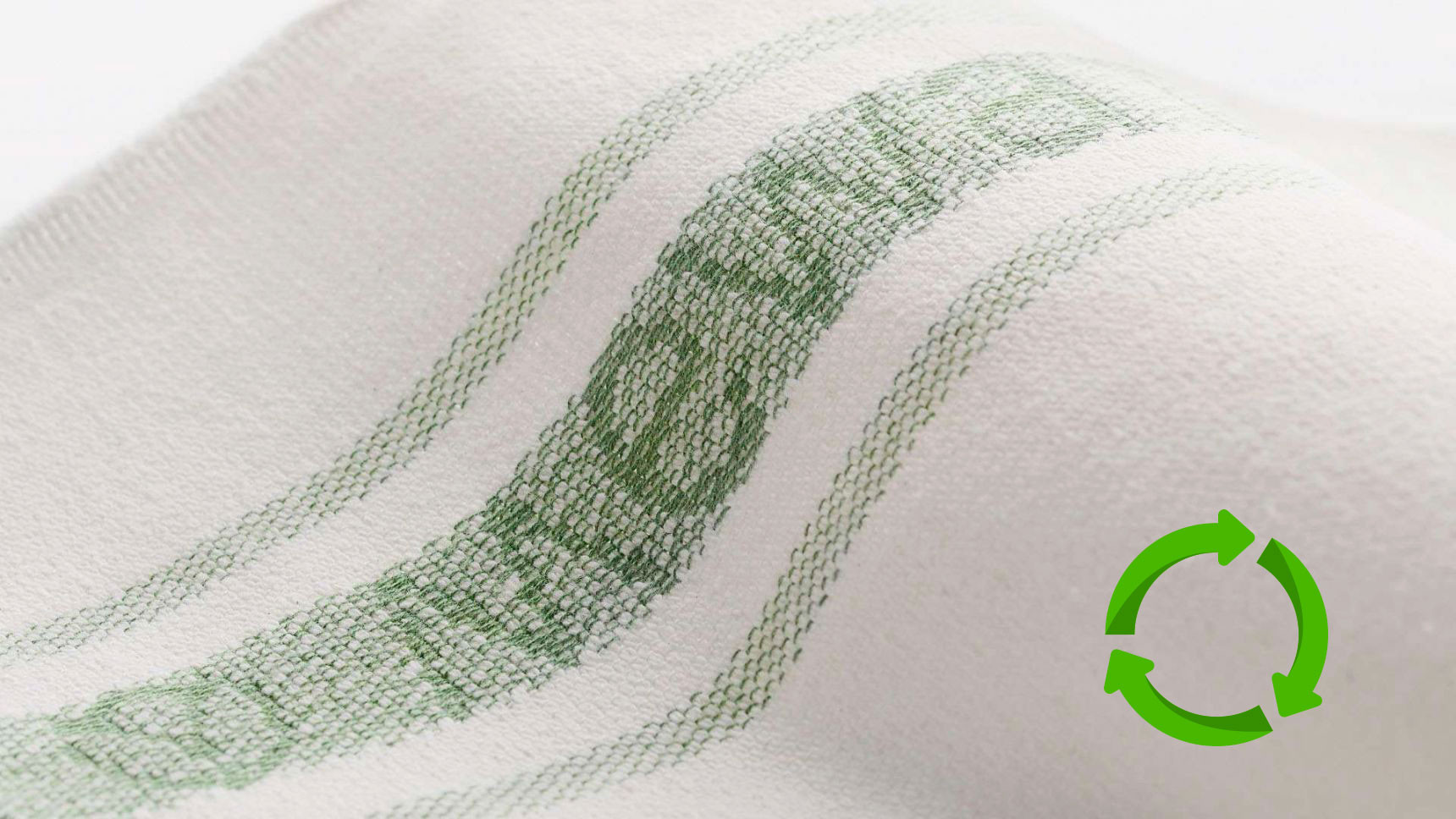

We limit the use of disposable materials to protect the environment.

The impact of disposable materials on the environment is a great challenge for everyone. Raising awareness and educating our collaborators in regards to the importance of increasing their attention to these issues in their work, is one of our good practices. And it was precisely the sensitivity of our company's employees that prompted them to replace the disposable towels used to clean the production departments with technical, multipurpose Mewa cloths.

This decision, which might appear insignificant, actually has an important and positive impact on the environment insofar as the cloths can be reused multiple times before being returned to Mewa, which then washes them with biodegradable detergents with an eye to energy consumption.

Discover how we improve our impact in other common benefit goals

Take action for people

Our company is made up of people who share values and development projects. This goal is particularly important to us and we focus our efforts in five areas of action.

Climate action

Our impact on the environment is naturally linked to our manufacturing identity. We are fully aware of this and, therefore, constantly measure our impacts, assessing the relative opportunities and risks. This allows us to improve through numerous carefully planned initiatives.

Take action for the territory

Consideration of our local region and local community is a key aspect for us, acknowledging our responsibility to tackle aspects that go beyond standard entrepreneurial goals and beyond our borders. We want to work to the benefit of the local territory by contributing to research, inclusion and culture.